Ours Enterprise

Jinhua Hongjing Manufacturing Co., Ltd is the production and manufacturing center solely invested by Australian Archer – the worldwide top saw chain brand in 2012. The company is high-tech oriented and specialized in production of gardening tools and accessories. We are located at Jinhua City, Zhejiang Province in China, with an annual saw chain production capacity of 9 million feet. We have a variety of advanced production equipment, such as high-speed stamping, automatic heat treatment production lines, and full-automatic riveting production lines from the United States and Taiwan, China. To ensure the outstanding quality of our products, we have also established a physical and chemical testing center."Survive with quality and develop with reputation" is the purpose of the company. Our management policy is pursuing perfection, striving for excellence. ISO9001”Quality Management System” and ISO14001“Environmental Management System” are set up and continuously improved to ensure of all our products delivered with zero defects. We insist on satisfying customers and providing full service from innovation to after-sales service.Hongjing Manufacturing is willing to work together with all friends to create excellence and share brilliance!

Entering Hongjing

Ours Advantage

-

Sharp

Sharp -

Durable

Durable -

Safety

Safety -

Not Be Stretched

Not Be Stretched

-

punching

punching -

heat treatment

heat treatment -

processing

processing -

assembly

assembly -

packaging

packaging

Ours News

-

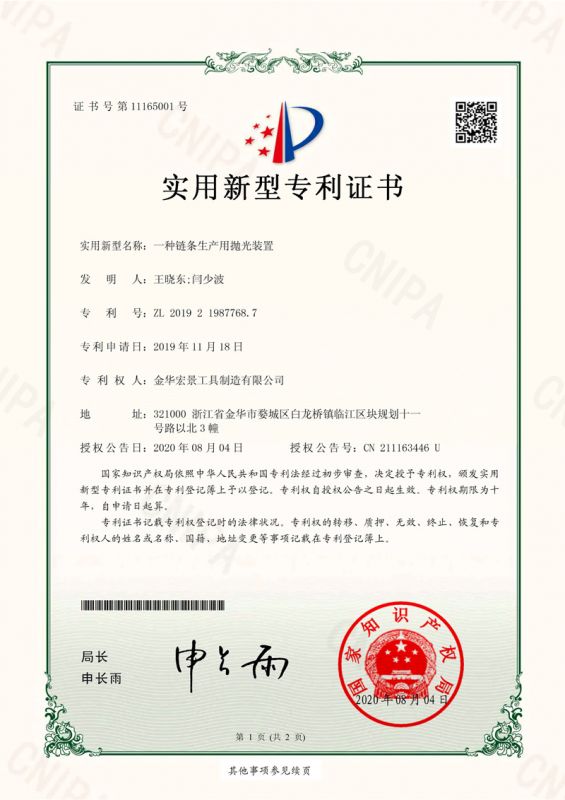

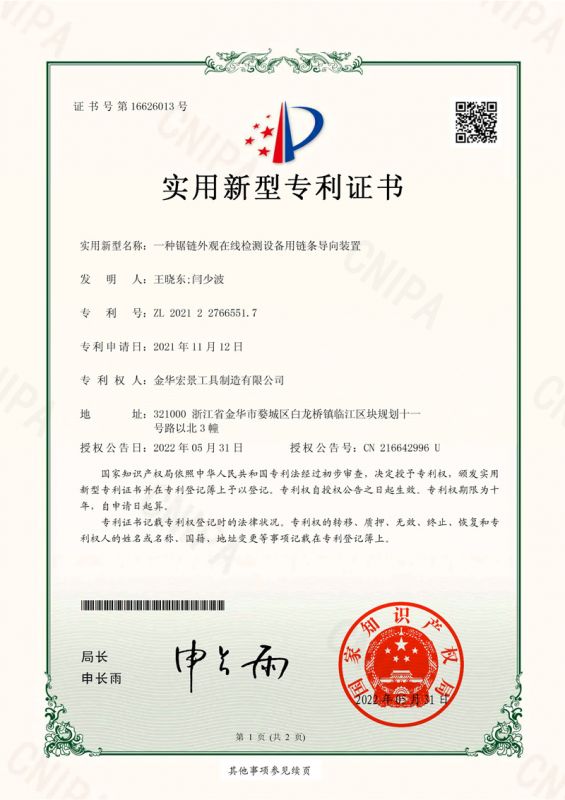

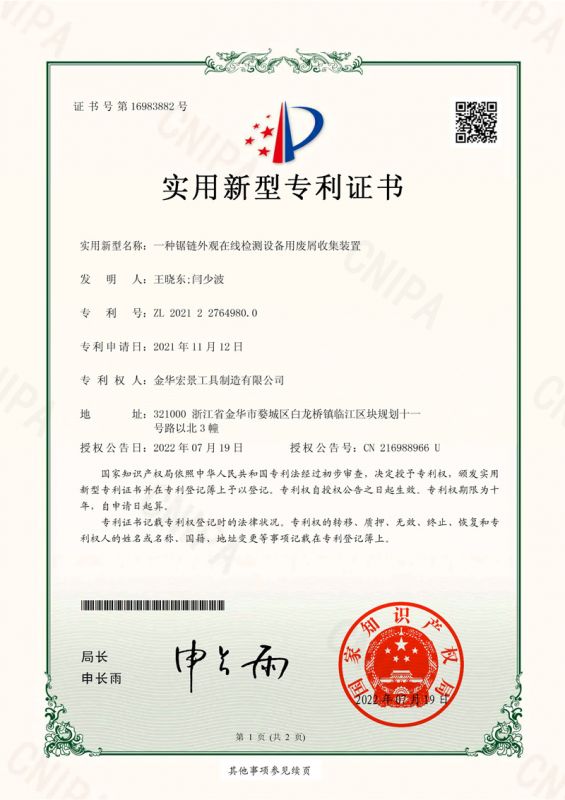

100% inspection of products produced by the factory to ensure zero defects before production and all cleaning and oiling before packagingThe factory has increased on-line testing equipment, which not only improves the passing rate of the inspection, but also reduces the visual fatigue of the old-fashioned manual inspection.The factory has a physical and chemical laboratory, which has a microscope, optical instruments such as the second element, to check the quality of products.2023-08-22

100% inspection of products produced by the factory to ensure zero defects before production and all cleaning and oiling before packagingThe factory has increased on-line testing equipment, which not only improves the passing rate of the inspection, but also reduces the visual fatigue of the old-fashioned manual inspection.The factory has a physical and chemical laboratory, which has a microscope, optical instruments such as the second element, to check the quality of products.2023-08-22 -

Safe operation of electric chain saws - Safety regulations for the use of electric chain sawsElectric chain saw is a woodworking electric tool that uses a rotating chain saw blade for cutting. Below, the editor will specifically introduce the safety regulations and general requirements for the use of electric links, tell everyone the preparation work and operation methods during operation, and introduce the maintenance and precautions before operation of electric chain saws. We hope it can be helpful to everyone. Come and take a look!1. Safety regulations for the use of electric chain saws1、 Scope: This standard specifies the safety requirements for the use of electric chain saws. This standard is applicable to electric chain saws for timber production in timber yards and other uses of electric chain saws.2、 Referenced standards? The provisions contained in the following standards, through reference in this standard, constitute the provisions of this standard. At the time of publication of this standard, all versions shown are valid. All standards used will be revised, and parties using this standard should explore the possibility of using the latest versions of the following standards. GB 3883.1-1991 Safety of Handheld Electric Power Tools Part 1: General Requirements (for Certification) GB 3883.14-1993 Safety of Handheld Electric Power Tools Part 2: Specific Requirements for Electric Chain Saws3、 Safety operating procedures?Warning: Accidental accidents during the use of electric chain saws that cause personal injury and property damage must be borne by the operator and user unit.General requirements?The electric chain saw should comply with the provisions of GB 3883.1 and GB 3883.14.The operator must be familiar with the performance and operating methods of the electric chain saw, and be able to operate and maintain it correctly according to the user manual.The operator must have received training and hold a work permit, and the following personnel are not allowed to operate the electric chain saw:a) Minors and elderly people;b) People who are physically weak or disabled;c) People who drink or take narcotic drugs.3.2.4 Do not operate the electric chain saw under the following circumstances:a) When someone approaches;b) Before the auxiliary personnel for material production withdraw to a safe area;c) Unstable stacking of original strips in the work area;d) Insufficient light;e) On rainy days, in open spaces with wind speeds greater than level 5 and thunderstorms;f) When there is no chain breakage protection device or rebound protection device, or when the device is damaged.prepareSafety shoes must be worn during homework.During homework, it is not allowed to wear oversized or open clothes and shorts, as well as accessories such as ties, bracelets, ankles, etc.3. Carefully check the wear level and tension of components such as the saw chain, guide plate, and sprocket, and make necessary adjustments and replacements.4. Check whether the electric chain saw switch is intact, whether the power connector is firmly connected, and whether the cable insulation layer is worn.Thoroughly inspect the work site and remove stones, metal objects, branches, and other discarded materials.Before starting the operation, it is necessary to select a safe evacuation channel and a safe area.operationWhen the original strip being processed is within 1.5m of the conveyor, operation is not allowed.Before connecting to the power supply, the electric chain saw switch must be turned off to prevent accidental start-up.3 Before making materials, start the electric chain saw to idle for 1 min, and check whether it operates normally.When starting or operating, hands and feet should not be close to rotating parts, especially the upper and lower parts of the chainWhen a fuse is blown or a relay trips, immediate inspection should be carried out.6. Do not overload the circuit and do not connect high-capacity fuses.The electric chain saw must be operated with both hands.During homework, it is important to stand firmly and not operate under or on logs that may roll.When troubleshooting saw clamping faults, special attention should be paid to the safety of auxiliary personnel.During the operation, the sawing mechanism should be lubricated and cooled at all times.When the original saw is about to break, pay attention to the movement of the wood and quickly lift the electric chain saw after the cut.When transferring operations, the electric chain saw switch must be turned off first, and running is not allowed during the transfer.Immediately cut off the power supply in the following situations:a) When the saw chain encounters other objects and needs to be checked for damage before restarting;b) When abnormal sound or vibration occurs during operation and it is necessary to check and troubleshoot;c) When the operator leaves the electric chain saw;d) When discovering the movement of nearby logs or logs;e) When sawing with sawing tools;f) When leakage is detected;4、 At the end of the assignmentAfter daily work, all nuts, bolts, and screws should be tightened, the wear level of the saw chain, guide plate, and sprocket should be checked, and necessary adjustments and replacements should be made.Check the wear of the power plug and cable insulation layer, and if any damage is found, replace or repair it in a timely manner.Before long-term storage, residual wood chips and dirt should be cleaned, the saw chain and guide plate should be removed and coated with anti rust oil. The motor should be protected against dust.It should be stored in a dry environment.2. Maintenance of electric chain sawsThe chain and guide plate should not be too tight. When the electric chain saw is working, lubricating oil should be applied every 10 minutes to not only maintain the guide plate but also the chain. At the same time, the variable box of the electric chain saw also needs to be replaced with yellow glycerin every year, and the motor needs to be replaced with carbon brushes frequently, approximately every six months.3 Safe operationPrecautions before operation:1. Safety shoes must be worn during work.2. During homework, it is not allowed to wear oversized or open clothes and shorts, as well as accessories such as ties, bracelets, ankles, etc.3. Carefully check the wear level and tension of components such as the saw chain, guide plate, and sprocket, and make necessary adjustments and replacements.4. Check whether the electric chain saw switch is intact, whether the power connector is firmly connected, and whether the cable insulation layer is worn.5. Thoroughly inspect the work site and remove stones, metal objects, branches, and other discarded materials.6. Before starting the operation, it is necessary to select a safe evacuation channel and safety zone.operation1. When the original strip being processed is within 1.5m of the conveyor, operations are not allowed.2. Before connecting to the power supply, the electric chain saw switch must be turned off to prevent accidental start-up.3. Before making materials, start the electric chain saw to idle for 1 min, and check whether it operates normally.4. When starting or operating, hands and feet should not be close to rotating parts, especially the upper and lower parts of the chain5. When a fuse is blown or a relay trips, immediate inspection should be carried out.6. Do not overload the circuit and do not connect high capacity fuses.7. The electric chain saw must be operated with both hands.8. When doing homework, it is important to stand firmly and not operate under or on logs or logs that may roll.9. When troubleshooting saw clamping faults, special attention should be paid to the safety of auxiliary personnel.10. During the operation, the sawing mechanism should be lubricated and cooled at all times.11. When the original blade is about to be sawn off, attention should be paid to the movement of the wood and the electric chain saw should be quickly lifted after the saw is cut off.12. When transferring operations, the electric chain saw switch must be turned off first, and running is not allowed during the transfer.Do not operate the electric chain saw under the following circumstances.1. When someone approaches2. Before the auxiliary personnel for material production withdraw to a safe area;3. Unstable stacking of original strips in the work area;4. Insufficient light;5. On rainy days, in open spaces with wind speeds greater than level 5 and thunderstorms;6. When there is no chain breakage protection device or rebound protection device, or when the device is damaged.2023-07-01

Safe operation of electric chain saws - Safety regulations for the use of electric chain sawsElectric chain saw is a woodworking electric tool that uses a rotating chain saw blade for cutting. Below, the editor will specifically introduce the safety regulations and general requirements for the use of electric links, tell everyone the preparation work and operation methods during operation, and introduce the maintenance and precautions before operation of electric chain saws. We hope it can be helpful to everyone. Come and take a look!1. Safety regulations for the use of electric chain saws1、 Scope: This standard specifies the safety requirements for the use of electric chain saws. This standard is applicable to electric chain saws for timber production in timber yards and other uses of electric chain saws.2、 Referenced standards? The provisions contained in the following standards, through reference in this standard, constitute the provisions of this standard. At the time of publication of this standard, all versions shown are valid. All standards used will be revised, and parties using this standard should explore the possibility of using the latest versions of the following standards. GB 3883.1-1991 Safety of Handheld Electric Power Tools Part 1: General Requirements (for Certification) GB 3883.14-1993 Safety of Handheld Electric Power Tools Part 2: Specific Requirements for Electric Chain Saws3、 Safety operating procedures?Warning: Accidental accidents during the use of electric chain saws that cause personal injury and property damage must be borne by the operator and user unit.General requirements?The electric chain saw should comply with the provisions of GB 3883.1 and GB 3883.14.The operator must be familiar with the performance and operating methods of the electric chain saw, and be able to operate and maintain it correctly according to the user manual.The operator must have received training and hold a work permit, and the following personnel are not allowed to operate the electric chain saw:a) Minors and elderly people;b) People who are physically weak or disabled;c) People who drink or take narcotic drugs.3.2.4 Do not operate the electric chain saw under the following circumstances:a) When someone approaches;b) Before the auxiliary personnel for material production withdraw to a safe area;c) Unstable stacking of original strips in the work area;d) Insufficient light;e) On rainy days, in open spaces with wind speeds greater than level 5 and thunderstorms;f) When there is no chain breakage protection device or rebound protection device, or when the device is damaged.prepareSafety shoes must be worn during homework.During homework, it is not allowed to wear oversized or open clothes and shorts, as well as accessories such as ties, bracelets, ankles, etc.3. Carefully check the wear level and tension of components such as the saw chain, guide plate, and sprocket, and make necessary adjustments and replacements.4. Check whether the electric chain saw switch is intact, whether the power connector is firmly connected, and whether the cable insulation layer is worn.Thoroughly inspect the work site and remove stones, metal objects, branches, and other discarded materials.Before starting the operation, it is necessary to select a safe evacuation channel and a safe area.operationWhen the original strip being processed is within 1.5m of the conveyor, operation is not allowed.Before connecting to the power supply, the electric chain saw switch must be turned off to prevent accidental start-up.3 Before making materials, start the electric chain saw to idle for 1 min, and check whether it operates normally.When starting or operating, hands and feet should not be close to rotating parts, especially the upper and lower parts of the chainWhen a fuse is blown or a relay trips, immediate inspection should be carried out.6. Do not overload the circuit and do not connect high-capacity fuses.The electric chain saw must be operated with both hands.During homework, it is important to stand firmly and not operate under or on logs that may roll.When troubleshooting saw clamping faults, special attention should be paid to the safety of auxiliary personnel.During the operation, the sawing mechanism should be lubricated and cooled at all times.When the original saw is about to break, pay attention to the movement of the wood and quickly lift the electric chain saw after the cut.When transferring operations, the electric chain saw switch must be turned off first, and running is not allowed during the transfer.Immediately cut off the power supply in the following situations:a) When the saw chain encounters other objects and needs to be checked for damage before restarting;b) When abnormal sound or vibration occurs during operation and it is necessary to check and troubleshoot;c) When the operator leaves the electric chain saw;d) When discovering the movement of nearby logs or logs;e) When sawing with sawing tools;f) When leakage is detected;4、 At the end of the assignmentAfter daily work, all nuts, bolts, and screws should be tightened, the wear level of the saw chain, guide plate, and sprocket should be checked, and necessary adjustments and replacements should be made.Check the wear of the power plug and cable insulation layer, and if any damage is found, replace or repair it in a timely manner.Before long-term storage, residual wood chips and dirt should be cleaned, the saw chain and guide plate should be removed and coated with anti rust oil. The motor should be protected against dust.It should be stored in a dry environment.2. Maintenance of electric chain sawsThe chain and guide plate should not be too tight. When the electric chain saw is working, lubricating oil should be applied every 10 minutes to not only maintain the guide plate but also the chain. At the same time, the variable box of the electric chain saw also needs to be replaced with yellow glycerin every year, and the motor needs to be replaced with carbon brushes frequently, approximately every six months.3 Safe operationPrecautions before operation:1. Safety shoes must be worn during work.2. During homework, it is not allowed to wear oversized or open clothes and shorts, as well as accessories such as ties, bracelets, ankles, etc.3. Carefully check the wear level and tension of components such as the saw chain, guide plate, and sprocket, and make necessary adjustments and replacements.4. Check whether the electric chain saw switch is intact, whether the power connector is firmly connected, and whether the cable insulation layer is worn.5. Thoroughly inspect the work site and remove stones, metal objects, branches, and other discarded materials.6. Before starting the operation, it is necessary to select a safe evacuation channel and safety zone.operation1. When the original strip being processed is within 1.5m of the conveyor, operations are not allowed.2. Before connecting to the power supply, the electric chain saw switch must be turned off to prevent accidental start-up.3. Before making materials, start the electric chain saw to idle for 1 min, and check whether it operates normally.4. When starting or operating, hands and feet should not be close to rotating parts, especially the upper and lower parts of the chain5. When a fuse is blown or a relay trips, immediate inspection should be carried out.6. Do not overload the circuit and do not connect high capacity fuses.7. The electric chain saw must be operated with both hands.8. When doing homework, it is important to stand firmly and not operate under or on logs or logs that may roll.9. When troubleshooting saw clamping faults, special attention should be paid to the safety of auxiliary personnel.10. During the operation, the sawing mechanism should be lubricated and cooled at all times.11. When the original blade is about to be sawn off, attention should be paid to the movement of the wood and the electric chain saw should be quickly lifted after the saw is cut off.12. When transferring operations, the electric chain saw switch must be turned off first, and running is not allowed during the transfer.Do not operate the electric chain saw under the following circumstances.1. When someone approaches2. Before the auxiliary personnel for material production withdraw to a safe area;3. Unstable stacking of original strips in the work area;4. Insufficient light;5. On rainy days, in open spaces with wind speeds greater than level 5 and thunderstorms;6. When there is no chain breakage protection device or rebound protection device, or when the device is damaged.2023-07-01 -

What is the use of a chain saw? Precautions for using a chain saw cutting machine. Use of chain saw oilChain saw is a portable saw powered by a gasoline engine, mainly used for logging and timber making. Its working principle is to use the cross movement of L-shaped blades on the saw chain for shearing action. So what are the precautions when using a chain saw? There must always be a slight splash of oil on the chain. Before starting work, it is necessary to check the lubrication of the saw chain and the oil level in the lubrication oil tank. The chain cannot work without lubrication, as working with a dry chain can cause damage to the cutting device. How to use chain saw oil? Below is a specific introduction for everyone, hoping to be helpful. Come and take a look!1、 DefinitionChain saw machine, also known as chain saw, is a portable saw powered by a gasoline engine. It is mainly used for logging and timber making, and its working principle is to use the cross movement of L-shaped blades on the saw chain to perform shearing action2、 CategoryChain saws are a type of demolition equipment that can be divided into motorized chain saws, non motorized chain saws, concrete chain saws, etc. based on their functions and driving methods.3、 What is the use of a chain sawIt is widely used in forestry production, such as logging, pruning, and timber making. It is an essential tool used in forest logging, timber making, pruning, as well as in operations such as logging in storage yards and railway sleeper sawing.4、 Precautions1. Regularly check the tension of the saw chain. When checking and adjusting, please turn off the engine and wear protective gloves. The appropriate tension is when the chain is hung under the guide plate and can be pulled by hand.2. There must always be a slight splash of oil on the chain. Before starting work, it is necessary to check the lubrication of the saw chain and the oil level in the lubrication oil tank. The chain cannot work without lubrication, as working with a dry chain can cause damage to the cutting device.3. Never use old engine oil. Old engine oil cannot meet lubrication requirements and is not suitable for chain lubrication.If the oil level in the oil tank does not decrease, it may be due to a malfunction in the lubrication delivery. Chain lubrication and oil circuits should be checked. Passing through contaminated filters can also lead to poor lubrication oil supply. The lubricating oil filter screen in the oil tank and pump connection pipeline should be cleaned or replaced.5. After replacing and installing a new chain, the saw chain requires 2 to 3 minutes of running in time. After running in, check the chain tension and readjust it if necessary. A new chain requires more frequent tensioning than a chain that has been in use for some time. When in a cold state, the saw chain must adhere to the lower part of the guide plate, but it can be moved by hand on the upper guide plate. If necessary, tension the chain again. When the operating temperature is reached, the saw chain expands and sags slightly, and the transmission joint at the lower part of the guide plate cannot detach from the chain groove, otherwise the chain will jump and need to be re tensioned.6. The chain must be relaxed after work. The chain will contract during cooling, and chains that are not loosened will damage the crankshaft and bearings. If the chain is tensioned during operation, it will contract during cooling, and if the chain is too tight, it will damage the crankshaft and bearings.5、 Use of Chain Saw OilThe chain saw requires the use of gasoline, engine oil, and chain saw chain lubricant:1. Only unleaded gasoline of grade 90 or above can be used for gasoline. When adding gasoline, the fuel tank cap and the surrounding area of the fuel filler must be cleaned before refueling to prevent debris from entering the fuel tank. The high branch saw should be placed on a flat surface with the fuel tank cover facing upwards. When refueling, do not let gasoline spill out or fill the fuel tank too full. After refueling, make sure to tighten the fuel tank cap as tightly as possible by hand.2. Only high-quality two-stroke engine oil can be used to ensure a longer service life of the engine. Do not use ordinary four-stroke engines. When using other two-stroke engine oils, their model should reach a tc grade quality. Poor quality gasoline or engine oil can damage the engine, sealing rings, oil ducts, and fuel tanks.3. The mixing ratio of gasoline and engine oil: Use a two-stroke engine oil specifically designed for high branch saw engines at a ratio of 1:50, which means adding 50 parts of gasoline to 1 part of engine oil; The use of other engine oils that meet the TC level is 1:25, which means 1 part of engine oil plus 25 parts of gasoline. The mixing method is to pour engine oil into a fuel tank that allows for fuel, then fill it with gasoline, and mix evenly. The gasoline engine oil mixture will age, and the general configuration amount should not exceed one month's usage. Special attention should be paid to avoiding direct contact between gasoline and the skin, and to avoid breathing the gas that evaporates from gasoline.4. Use high-quality chain saw chain lubricating oil to maintain the lubricating oil level no lower than the oil level to reduce wear on the chain and teeth. Due to the complete discharge of chain saw lubricating oil into the environment, ordinary lubricating oil is petroleum based and non degradable, which can pollute the environment. It is recommended to use biodegradable and environmentally friendly chain saw oil as much as possible. Many developed countries have strict regulations to avoid environmental pollution.2023-07-01

What is the use of a chain saw? Precautions for using a chain saw cutting machine. Use of chain saw oilChain saw is a portable saw powered by a gasoline engine, mainly used for logging and timber making. Its working principle is to use the cross movement of L-shaped blades on the saw chain for shearing action. So what are the precautions when using a chain saw? There must always be a slight splash of oil on the chain. Before starting work, it is necessary to check the lubrication of the saw chain and the oil level in the lubrication oil tank. The chain cannot work without lubrication, as working with a dry chain can cause damage to the cutting device. How to use chain saw oil? Below is a specific introduction for everyone, hoping to be helpful. Come and take a look!1、 DefinitionChain saw machine, also known as chain saw, is a portable saw powered by a gasoline engine. It is mainly used for logging and timber making, and its working principle is to use the cross movement of L-shaped blades on the saw chain to perform shearing action2、 CategoryChain saws are a type of demolition equipment that can be divided into motorized chain saws, non motorized chain saws, concrete chain saws, etc. based on their functions and driving methods.3、 What is the use of a chain sawIt is widely used in forestry production, such as logging, pruning, and timber making. It is an essential tool used in forest logging, timber making, pruning, as well as in operations such as logging in storage yards and railway sleeper sawing.4、 Precautions1. Regularly check the tension of the saw chain. When checking and adjusting, please turn off the engine and wear protective gloves. The appropriate tension is when the chain is hung under the guide plate and can be pulled by hand.2. There must always be a slight splash of oil on the chain. Before starting work, it is necessary to check the lubrication of the saw chain and the oil level in the lubrication oil tank. The chain cannot work without lubrication, as working with a dry chain can cause damage to the cutting device.3. Never use old engine oil. Old engine oil cannot meet lubrication requirements and is not suitable for chain lubrication.If the oil level in the oil tank does not decrease, it may be due to a malfunction in the lubrication delivery. Chain lubrication and oil circuits should be checked. Passing through contaminated filters can also lead to poor lubrication oil supply. The lubricating oil filter screen in the oil tank and pump connection pipeline should be cleaned or replaced.5. After replacing and installing a new chain, the saw chain requires 2 to 3 minutes of running in time. After running in, check the chain tension and readjust it if necessary. A new chain requires more frequent tensioning than a chain that has been in use for some time. When in a cold state, the saw chain must adhere to the lower part of the guide plate, but it can be moved by hand on the upper guide plate. If necessary, tension the chain again. When the operating temperature is reached, the saw chain expands and sags slightly, and the transmission joint at the lower part of the guide plate cannot detach from the chain groove, otherwise the chain will jump and need to be re tensioned.6. The chain must be relaxed after work. The chain will contract during cooling, and chains that are not loosened will damage the crankshaft and bearings. If the chain is tensioned during operation, it will contract during cooling, and if the chain is too tight, it will damage the crankshaft and bearings.5、 Use of Chain Saw OilThe chain saw requires the use of gasoline, engine oil, and chain saw chain lubricant:1. Only unleaded gasoline of grade 90 or above can be used for gasoline. When adding gasoline, the fuel tank cap and the surrounding area of the fuel filler must be cleaned before refueling to prevent debris from entering the fuel tank. The high branch saw should be placed on a flat surface with the fuel tank cover facing upwards. When refueling, do not let gasoline spill out or fill the fuel tank too full. After refueling, make sure to tighten the fuel tank cap as tightly as possible by hand.2. Only high-quality two-stroke engine oil can be used to ensure a longer service life of the engine. Do not use ordinary four-stroke engines. When using other two-stroke engine oils, their model should reach a tc grade quality. Poor quality gasoline or engine oil can damage the engine, sealing rings, oil ducts, and fuel tanks.3. The mixing ratio of gasoline and engine oil: Use a two-stroke engine oil specifically designed for high branch saw engines at a ratio of 1:50, which means adding 50 parts of gasoline to 1 part of engine oil; The use of other engine oils that meet the TC level is 1:25, which means 1 part of engine oil plus 25 parts of gasoline. The mixing method is to pour engine oil into a fuel tank that allows for fuel, then fill it with gasoline, and mix evenly. The gasoline engine oil mixture will age, and the general configuration amount should not exceed one month's usage. Special attention should be paid to avoiding direct contact between gasoline and the skin, and to avoid breathing the gas that evaporates from gasoline.4. Use high-quality chain saw chain lubricating oil to maintain the lubricating oil level no lower than the oil level to reduce wear on the chain and teeth. Due to the complete discharge of chain saw lubricating oil into the environment, ordinary lubricating oil is petroleum based and non degradable, which can pollute the environment. It is recommended to use biodegradable and environmentally friendly chain saw oil as much as possible. Many developed countries have strict regulations to avoid environmental pollution.2023-07-01

浙公网安备:浙公网安备33070202666801号

浙公网安备:浙公网安备33070202666801号