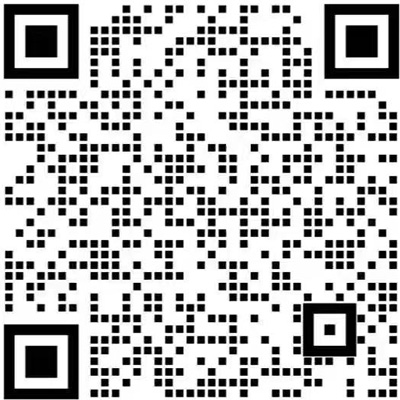

Service hotline:0579-82591729

E-mail:Daisy@archersawchain.com

Address:The area east of Linqian Longyi Road, south of Linqian Hengyi Road, and north of Linqian Hengsi Road in Qianxi Township, Wucheng District, Jinhua City, Zhejiang Province

Chain saw is a portable saw powered by a gasoline engine, mainly used for logging and timber making. Its working principle is to use the cross movement of L-shaped blades on the saw chain for shearing action. So what are the precautions when using a chain saw? There must always be a slight splash of oil on the chain. Before starting work, it is necessary to check the lubrication of the saw chain and the oil level in the lubrication oil tank. The chain cannot work without lubrication, as working with a dry chain can cause damage to the cutting device. How to use chain saw oil? Below is a specific introduction for everyone, hoping to be helpful. Come and take a look!

1、 Definition

Chain saw machine, also known as chain saw, is a portable saw powered by a gasoline engine. It is mainly used for logging and timber making, and its working principle is to use the cross movement of L-shaped blades on the saw chain to perform shearing action

2、 Category

Chain saws are a type of demolition equipment that can be divided into motorized chain saws, non motorized chain saws, concrete chain saws, etc. based on their functions and driving methods.

3、 What is the use of a chain saw

It is widely used in forestry production, such as logging, pruning, and timber making. It is an essential tool used in forest logging, timber making, pruning, as well as in operations such as logging in storage yards and railway sleeper sawing.

4、 Precautions

1. Regularly check the tension of the saw chain. When checking and adjusting, please turn off the engine and wear protective gloves. The appropriate tension is when the chain is hung under the guide plate and can be pulled by hand.

2. There must always be a slight splash of oil on the chain. Before starting work, it is necessary to check the lubrication of the saw chain and the oil level in the lubrication oil tank. The chain cannot work without lubrication, as working with a dry chain can cause damage to the cutting device.

3. Never use old engine oil. Old engine oil cannot meet lubrication requirements and is not suitable for chain lubrication.

If the oil level in the oil tank does not decrease, it may be due to a malfunction in the lubrication delivery. Chain lubrication and oil circuits should be checked. Passing through contaminated filters can also lead to poor lubrication oil supply. The lubricating oil filter screen in the oil tank and pump connection pipeline should be cleaned or replaced.

5. After replacing and installing a new chain, the saw chain requires 2 to 3 minutes of running in time. After running in, check the chain tension and readjust it if necessary. A new chain requires more frequent tensioning than a chain that has been in use for some time. When in a cold state, the saw chain must adhere to the lower part of the guide plate, but it can be moved by hand on the upper guide plate. If necessary, tension the chain again. When the operating temperature is reached, the saw chain expands and sags slightly, and the transmission joint at the lower part of the guide plate cannot detach from the chain groove, otherwise the chain will jump and need to be re tensioned.

6. The chain must be relaxed after work. The chain will contract during cooling, and chains that are not loosened will damage the crankshaft and bearings. If the chain is tensioned during operation, it will contract during cooling, and if the chain is too tight, it will damage the crankshaft and bearings.

5、 Use of Chain Saw Oil

The chain saw requires the use of gasoline, engine oil, and chain saw chain lubricant:

1. Only unleaded gasoline of grade 90 or above can be used for gasoline. When adding gasoline, the fuel tank cap and the surrounding area of the fuel filler must be cleaned before refueling to prevent debris from entering the fuel tank. The high branch saw should be placed on a flat surface with the fuel tank cover facing upwards. When refueling, do not let gasoline spill out or fill the fuel tank too full. After refueling, make sure to tighten the fuel tank cap as tightly as possible by hand.

2. Only high-quality two-stroke engine oil can be used to ensure a longer service life of the engine. Do not use ordinary four-stroke engines. When using other two-stroke engine oils, their model should reach a tc grade quality. Poor quality gasoline or engine oil can damage the engine, sealing rings, oil ducts, and fuel tanks.

3. The mixing ratio of gasoline and engine oil: Use a two-stroke engine oil specifically designed for high branch saw engines at a ratio of 1:50, which means adding 50 parts of gasoline to 1 part of engine oil; The use of other engine oils that meet the TC level is 1:25, which means 1 part of engine oil plus 25 parts of gasoline. The mixing method is to pour engine oil into a fuel tank that allows for fuel, then fill it with gasoline, and mix evenly. The gasoline engine oil mixture will age, and the general configuration amount should not exceed one month's usage. Special attention should be paid to avoiding direct contact between gasoline and the skin, and to avoid breathing the gas that evaporates from gasoline.

4. Use high-quality chain saw chain lubricating oil to maintain the lubricating oil level no lower than the oil level to reduce wear on the chain and teeth. Due to the complete discharge of chain saw lubricating oil into the environment, ordinary lubricating oil is petroleum based and non degradable, which can pollute the environment. It is recommended to use biodegradable and environmentally friendly chain saw oil as much as possible. Many developed countries have strict regulations to avoid environmental pollution.

Hotline